Ford Racing Sportsman Block

Ford Racing Sportsman Block SCAT 4340 forged

lightweight crankshaft.

SCAT 4340 forged

lightweight crankshaft. General - Canfield Heads - CP Pistons - Accel DFI Intake - Pauter Rods - T&D Rockers - Assembly - Other Parts - Cam - Dyno Results

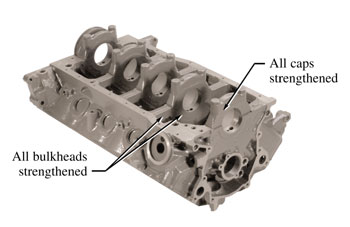

There has been a change in plans. I will be using a FRPP Sportsman block (part number M-6010-B50) instead of the high-nickel stock roller. Don Redmon, of Replika Maschinen was not impressed with the high-nickel block. His comments had to do with bolt sizes and such.

Ford Racing Sportsman Block

Ford Racing Sportsman Block |

SCAT 4340 forged

lightweight crankshaft. SCAT 4340 forged

lightweight crankshaft. |

|

Canfield Cylinder Heads

|

|

|

SMALL BLOCK FORD As Cast:

|

20450-58-0-B

|

|

Intake Valve Size:

|

2.02

|

|

Exhaust Valve Size:

|

1.60

|

|

Intake Port Volume:

|

192

|

|

Chamber Volume:

|

58

|

|

VALVE LIFT

|

.100

|

.200

|

.300

|

.400

|

.500

|

.600

|

.700

|

|

Intake Port

|

70

|

150

|

203.5

|

242

|

261.5

|

272

|

274

|

|

Exhaust Port*

|

54

|

102

|

132

|

171

|

190

|

201

|

207

|

| These are typical flow numbers at 28 inches of water measured

on a SF 600 bench by an independent shop. *Exhaust flow numbers are without a pipe. |

|||||||

| Raw |  |

|

|

|

|

|

|

Sorry about the fuzzy pictures. Next time I'm using a tri-pod. |

The porting work is being done by Replika Maschinen, in Santa Clara, CA. Don Redmon is an artist. You should check him out for your next project.

Head Porting Progress

|

|

|

| Things are looking pretty good. These are just the "roughing in" stages. | |

Head Porting Progress

|

| Here are some shots of the heads. They are not complete yet. The polishing still needs to be done as do the valve seats. | ||

|

|

|

Head Porting Progress

|

Head Porting Progress

|

|

Here we have a shot of the completed combustion chamber. The

valve job is done and the heads are ready to be bench flowed today. I'll

post the flow numbers just as soon as I get them.

|

CP Pistons

|

|

|

|

These pictures were taken late at night, but show you

what the pistons look like as they came from CP. I don't know

about you, but I think the look pretty sexy. :-D

|

|

Accel Intake Manifold

|

The bottom |

The front |

The top |

Looks like a pretty good casting to me |

#1 Runner |

#2 Runner |

#2 Runner |

#3 Runner |

#3 Runner |

#4 Runner |

#4 Runner |

#5 Runner |

#6 Runner |

#7 Runner |

#8 Runner |

View of a port |

Again... the porting work is being done by Replika Maschinen, of Santa Clara, CA.

Intake Porting Progress

|

| Here is a shot of the rough-in stage on the intake porting. |  |

Intake Porting Progress

|

The Connecting RodsFrom Pauter Machine |

T&D MachiningCompetition Rockers |

Elgin CamsHydraulic Roller Cam |

|

| This is the cam card for the Elgin hydraulic roller cam that we replaced. The power from this cam was phenominal, but the lifters could not keep up with it. You can see the dyno results below. I am replacing this cam with a solid-roller unit. There will be more details on the new cam soon. |

Engine WorkBuilding a 327 Stroker |

The Other Parts |

Dyno Results |

Dyno Results |